Supply Chain Woes

More Of The Same For 2022?

By all estimates, the demand for firearms and ammunition remains historically strong. According to NSSF, 2021 was the second-highest year on record for background checks — totaling 18.5 million. Concurrently, ongoing supply chain disruptions are creating obstacles for shooting sports manufacturers, distributors and dealers who are struggling to meet the increased demand.

Manufacturing facilities and port terminals around the world still face COVID-19 lockdowns. A shortage of shipping containers, equipment, vehicles and labor is exacerbating congestion at U.S. ports. Similarly, trucking and rail companies are hamstrung by a lack of workers. Unfortunately, the supply chain gridlock is expected to continue deep into 2022 and likely beyond.

How is the supply chain gridlock affecting gun stores and shooting ranges? Which products are the hardest to find these days? How are dealers navigating the supply chain challenges? What are manufacturers and wholesale distributors doing to help them?

To get answers to these questions and more, we spoke with Rex Gore, president/CEO of Black Wing Shooting Center in Delaware, Ohio; Mark Abramson, president of Los Ranchos Gun Shop in Albuquerque, N.M.; and Bob Porter, general manager of Oasis Outback in Uvalde, Texas. Brent Wouters, president and CEO at Iron Valley Supply Co. and Miles Hall, senior advisor at business-consulting group Hall-N-Hall in Edmond, Okla. offered their insights here, as well.

The Dealer Perspective

SI:How have the supply chain problems affected your store?

Gore: Like everyone in this industry, and most other industries, the supply chain has been broken since March 2020. As a result, it has been difficult to procure inventory in a timely manner and impossible to predict when what you have on order will be received. Although our industry has never been great, in more normal times you could at least predict within a few weeks when products would arrive. Today, it’s impossible unless you’re buying from a distributor who knows they have it in stock. Even non-firearm related items (office supplies, equipment, building supplies, etc.) we need are difficult to find at times. The impact has been we can’t sell what we don’t have, which has caused us to lose sales.

Additionally, customers don’t understand why we can’t give them a timeframe for delivery. During the height of the buying panic, this resulted in frustrated and angry customers who, unfortunately at times, took it out on our staff. At least now most people understand this is the new normal, and they’re more understanding of the wait times.

Abramson: We’ve experienced significant disruption in meeting the needs of our guests. Availability of ammunition across the spectrum has been a challenge. While there has been some occasional relief in handgun rounds, both for range and defense, the same has not been true for hunting rounds. We typically carry a breadth of options for hunting and old military rounds, but availability has been bleak. The same is true for shotgun rounds. While slugs and 00 buckshot have been available, rounds suitable for lighter loads and for upland, wetland and turkey hunting have been slim. Our orders for folks who want to try their hand at trap, skeet and sporting clays have impacted access.

SI:What do your inventory levels look like right now?

Porter: Inventories are short in some categories after a strong Christmas shopping season. Camo apparel being the most depleted with little to no replenishment opportunities.

Abramson: Inventory is a deceiving number. On the whole, we’re stocked with several hundred handguns. On the other hand, the holes are a real challenge to fill. We have been reluctant to order rifles or even take them in trade because we don’t have any assurance we’ll be able to find ammunition to run them. Many of the exciting newer calibers are a real challenge, as it’s difficult to sell a rifle if we do not have the ammunition to run it. The guest sees there’s no ammo and reaches her own conclusion the ammo is hard to find, resulting in a hesitancy to purchase. In the reloading area, powder, primers and projectiles are empty, and we’re only able to secure about 5% of the amount of powder we have on backorder at any time. Primers and bullets are a real challenge to secure.

Gore: Currently, our inventory levels are good and for the most part where we would like them to be this time of year. We worked hard in 2020–21 to source product from non-traditional sources, which allowed us to maintain inventory where others in our market were out of stock. Since we’re a full-service retail operation with indoor and outdoor ranges, training and a corporate event center, we had to maintain adequate levels of ammo inventory to operate. So, we bought deep, imported ammo and worked our relationships.

“We’ve experienced significant disruption in meeting the needs of our guests.”

Mark Abramson, President Los Ranchos Gun Shop, Albuquerque, N.M.

SI: Which products are the hardest to find these days?

Abramson: Primers, first and foremost. Smokeless powder because of restrictions on availability through importation and domestic demand. Of course, HAZMAT fees make smaller orders unfeasible. Manufacturers are introducing new products. Adding SKUs may be exciting in the marketplace, but really limits what we’re willing to take a chance with.

Gore: Currently for us, being a medium-size company in a buying group, supported by several great distributors, having been in business for 20+ years, we’re fortunate enough to have access to most everything we need across the firearm brands. Where supplies are low seem to be in the accessory lines which, unfortunately, mostly come from overseas where manufacturers have been hit harder with COVID.

Surprisingly, shotshells have been impossible to find over the past 18 months and have been in short supply until just recently for us. All hunting ammo — rifle, pistol and shotgun — has been tight and moves fast when we get it in. I think most people traditionally relied upon the big-box stores (Walmart, Cabela’s, etc.) for their ammo needs, and they seem to have less ammo than we do most of the time.

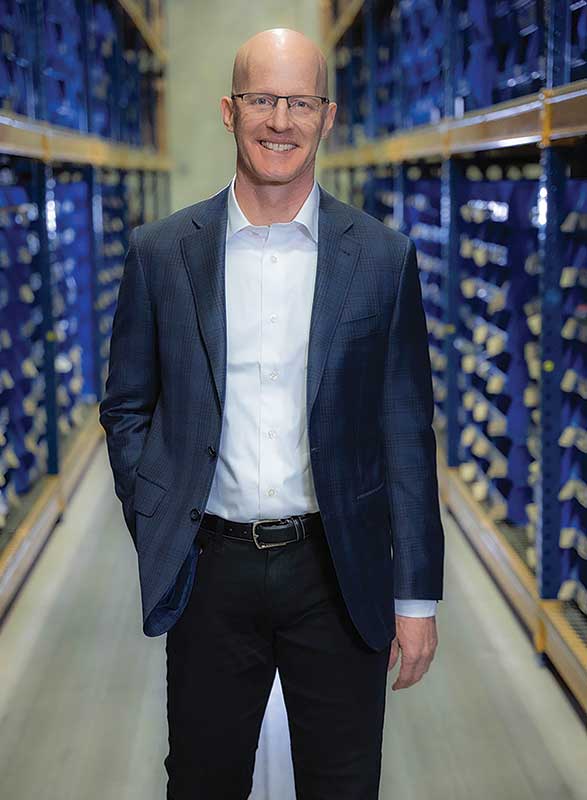

Rex Gore, president and CEO of Black Wing Shooting Center, has developed strong

relationships as a result of 20+ years in business. “We worked hard in 2020–21 to

source product from non-traditional sources, which allowed us to maintain inventory

where others in our market were out of stock. We bought deep, imported ammo and

worked our relationships,” he shared.

Porter: Our biggest challenge has been hunting ammunition. Especially high-demand calibers such as .243, .30-06, .22-250, .30-30, .300 Win. Mag., 7mm and .270 Win. to name a few. We had some .308 Win. and 6.5 Creedmoor through the season. Other than 9mm, handgun ammo has been hard to come by. We have a good bit of .223 and 5.56. Sales of these two have really diminished. Ruger gained availability as 2021 wore on. Smith & Wesson and Savage were our strongest through the year.

SI: What are you hearing from suppliers?

Abramson: Amazingly little. As a politician told me recently, sometimes COVID is the reason, and sometimes it’s an excuse. Suppliers across the board have simply ascribed shortages to the supply chain challenges, but manufacturers claim they’re making everything as fast as they can. Allocation of firearms and ammunition has encouraged over-ordering at all levels of the supply chain, and then dumping of products when it comes in. The industry has always been fiercely independent and tight-lipped about production scheduling. However, such silence tends to breed distrust and loss of consumer confidence. Moreover, some customers have been reaching out to manufacturers directly, and doing an end run around the distributor model. With so many products subject to distributor allocation, each distributor and their sales professionals have had to develop priorities as to which dealers win and lose in the fight to find saleable product.

Porter: I’m not hearing much positivity. Firearms and ammo forecasts from our factory reps indicate 2022 will be better, but barely so. Prices are not expected to see any reductions until a political administration change. Orders can be placed for imported goods, but delivery is hard to forecast for apparel, footwear, etc.

Gore: Mainly to expect more of the same. Product will continue to be coming out slowly due to the continued high demand and cost will continue to increase as component and labor costs continue to rise with inflation. New product announcements will be slow as most manufacturers are working hard to build staple product and not working to develop new lines. Most feel like this will be the new norm until at least 2023.

The thing we need to remember is unlike any of the other spikes in this industry I have been involved with over the last 25 years, is we have another 10 to 15 million new gun owners onboard since March of 2020. Even if only 50% of them stay engaged in the sport, demand for product should continue to remain strong as the new gun owners purchase additional firearms, ammo and take training.

SI: What advice do you have for other dealers struggling to keep product in stock?

Porter: For apparel and hard goods, order early and schedule delivery early. You may have to sit on it awhile, but it’s hard to do business out of an empty wagon. I think the firearm situation will be better for 2022 with some normalcy returning. I’m basing this on the fact we just received a small shipment of Remington firearms!

Lead, copper, brass and primer supplies will continue to hamper production of ammo, especially hunting ammo. I will roll 2021 factory ammo orders into 2022, with some adjustments, and use our distributor channel a little more by participating more in their early shows.

Abramson: Don’t over-order. While ordering 10 or 20 of one item at a time can be unnerving, it can be fatal if they actually all come in and you cannot move them. Be nimble and embrace online venues or aggressive pricing to have a chance at moving excess inventory. Also, keep close track of where you place backorders with distributors. Looking for a gun by casting a wide net could get you stuck with all backorders coming in at the same time. This may be fine for mass-produced handguns, but can be a real problem for special volume guns and accessories.

Gore: You have to work hard each day chasing product during times like now. It won’t always be this way and, unfortunately, the newer and smaller you are the harder it will be. Don’t make commitments to your customers you can’t keep. Do business with multiple vendors/distributors/manufacturers — as they say, don’t put all your eggs in one basket. Build relationships and volume with multiple key distributors, so when times are tough, hopefully you can get a little from each of them. Pay your bills on time and build a solid reputation for your company. If you have problems, be honest with your vendors. Lastly, manage your backorders and don’t get over-committed. There will be a day where inventory starts flowing and you don’t want to get buried with inventory you can’t pay for.

“I’m not hearing much positivity. Firearms and ammo forecasts from our factory reps indicate 2022 will be better, but barely so.”

Bob Porter, General Manager Oasis Outback, Uvalde, Texas

SI: How are you navigating these supply chain problems?

Gore: We’re working every day to procure product. Adjusting our backorders, placing new orders for future delivery, talking to manufacturers and distributors, keeping our liquidity available for opportunity purchases and building relationships with suppliers.

Porter: In early 2021, we placed orders to come in either ASAP or three to four months earlier than in previous years. It worked out well in most categories with the exception of firearms and ammo.

Abramson: We’ve been using the auto order function in our AXIS POS. However, allocated items are not available under this system. We continue to work with our sales professionals to curry favor and have opportunities for allocated items. We’re also a member of a buy-group, which has helped us get access to direct purchases with great success.

The Wholesale Distribution Perspective

SI: How have the supply chain challenges affected your business?

Wouters: We’ve seen two key impacts from the supply chain challenges. First, we had two overseas shipments delayed, one of which was delivered seven months late and the other was one month late. For the first delayed shipment, we missed the sales cycle for the product and thus experienced significantly lower margins on those products than anticipated (resulting in net losses on those products). For the second delayed shipment, we saw virtually no impact on sales, margins or customer service.

Second, we’ve seen an increase in shipping supply costs associated with the tighter supply chain and inflation. The resulting sizable increases in boxes, packing materials and tape have increased our supply costs by 30% independent of our growth in volume.

SI: Which items have been the most difficult to get?

Wouters: Typically, the most difficult items to get are products that don’t represent the core profit-generating products for our suppliers. With limited capacity and very high demand, our suppliers have streamlined production to only the highest-margin products and thus do not fill our orders for lower-volume or less-profitable products in their offerings.

SI: What are you hearing from the manufacturers? What are they doing to address the situation?

Wouters: While manufacturers are cautious about adding capacity, most are actively adding some capacity while making production choices to optimize their profitability and throughput. Our suppliers are adding new production capacity, new technology to improve throughput and adding back certain lower-volume products to fill out their product availability.

SI: How are you navigating these supply chain problems?

Wouters: To avoid supply chain challenges, we have eliminated certain product lines from overseas suppliers who don’t ship reliably or generate meaningful profits for our business. We largely have maintained all supply relationships and improved our communication to ensure desired products are shipped on time, and by and large, we haven’t had to make substantial changes due to the supply chain constraints.

SI: How long do you believe the global supply problems will last?

Wouters: Supply challenges related to ocean freight and trucking will persist throughout 2022 and 2023. Long before COVID, U.S. seaports suffered from significant inefficiencies in unloading and truck/rail access due to highway and rail infrastructure limitations and underinvestment. COVID simply exacerbated the problem and made it more evident to the broader business community.

Our lack of investment in seaports, airports, trucking, rail and highways has caused significant supply disruptions and inflated costs for many years, and our current supply chain challenges will be only partially alleviated with a decline in COVID. Thus, I believe the supply chain challenges will persist, but they may moderate after 2022.

The Consultant Perspective

SI: How can FFL dealers successfully navigate the current supply chain problems?

Hall: The better your records, the easier it is to survive the hiccups that are all too normal for our industry. Comparing sales of items to previous years, months and seasons is the first big one, then there is the turnover rate of the items. These are the first two big areas to get your arms around.

Lastly, listening to your sales team on what they’re hearing from guests will always be more accurate than just a wild guess. This pattern, once developed, will help incredibly well in the future. Dealers are smart and caring folks. You can do this. It’s a procedure that, once in place, will be easy to follow and potentially worth millions in sales for your store.

SI: What’s the number-one thing dealers can do right now to fill their pegs?

Hall: Knowing what you actually have in stock right now. I know it sounds like a “duh” moment, but in our travels, we’ve found far too many dealers who don’t know. They have a “feeling” or a “sense” and often they’re actually way off. In short, you need to know what needs to be ordered so it can be put into the wholesaler’s queue order to get them. Some of our industry wholesalers specialize in specific brands. Knowing this will also help in getting those items.

SI: When it comes to buying, how can a store stand out?

Hall: Successful buying is an art, and you can learn it. Planning outwears in advance is also very important. Giving distributors your “wish list” will be looked on as you are a step above the others. This will not only get you respect, but also, more importantly, product. Will there be a few misses and even messes? Yes, but you can survive those by gathering data, listening to your sales team and, of course, paying your bill promptly. The distributors will go to the ends of the earth for you as long as they believe you will work together.

How important is it to work with multiple distributors?

Hall: The industry has many wonderful wholesaler outlets also known as distributors. Their function is to provide the products you need as best they can. Many of them specialize in certain areas or product brands. The better you share your data the better they will be able to help you. I know the sales staff of these groups can be very persuasive, which has value, but it’s your business and ultimately you have to pay the bill for any items shipped.

Comparing between groups will help you. Try and find one that fits your store’s product line and your spirit. Give them most of your buys so you can work up the priority list with them. Then spread out other items in a similar fashion with the next and so on. Successful dealers will use typically about four distributors until they reach $5 million sales figures and then add one more (roughly) every $2 to $3 million in added sales. Eventually you’ll be a top-tier buyer from each distributor and making more margin than ever.

Editor’s Note: Portions of this article were not included in the print issue of Shooting Industry.